Valve Manufacturers in Saudi Arabia: An Industrial Buyer’s Practical Guide

The industrial backbone of Saudi Arabia is made on oil & gas, petrochemicals, power generation, water treatment and on the large-scale infrastructure projects too. In each of these sectors, valves are not only elements but they are more than that. These are safety devices, control elements and reliability enablers. This is why the selection of the right valve manufacturers in Saudi Arabia is a decision which will directly affect plant performance, maintenance costs and will affect operational safety too.

If you are an engineer, technician, or even procurement professional working in Saudi Arabia, you have probably seen how a poorly selected valve can cause leakage, unplanned shutdowns, or even safety incidents. This guide is written from a practical, on-site perspective to help you understand the local valve market, the kinds of valves in piping, and how flange selection and automation integration fit into real industrial conditions.

The Importance of Valves in Saudi Arabia’s Industrial Landscape

Saudi Arabia operates some of the most demanding industrial facilities in the world like high ambient temperatures, corrosive fluids, high-pressure pipelines and their continuous operation are the common challenges. In such conditions, valves must perform trustworthy year after year.

This is where skilled valve manufacturers in Saudi Arabia and authorized suppliers become important. Local availability always ensures the faster lead times, easier compliance with Saudi Aramco and SABIC standards and also access to the technical support when any problems arise. Instead of relying solely on overseas shipments, many plants prefer those suppliers who are with strong regional knowledge and the stock.

Organizations like Quality & Innovation give their support to Saudi industries by supplying industrial valves, automation products and all of the instrumentation solutions which align with international standards and local operating requirements.

Valve Manufacturers in Saudi Arabia: Local Presence vs. Global Supply

The valve market in Saudi Arabia is a mix of local manufacturers, regional distributors and all the global brands with authorized representatives. Each of them plays a specific role.

Local manufacturing and their assembling facilities offer quicker turnaround and customization for each specific project. International brands, on the other hand, bring decades of proven performance and global certifications too. Most large projects in Saudi Arabia rely on a combination of both global brands who supply via the trusted local partners.

Local manufacturing and assembly facilities offer quicker turnaround and customization for each specific project. International brands, on the other hand, bring decades of proven performance and global certifications too. Most large projects in Saudi Arabia rely on a combination of both global brands who supply via trusted local partners.

When evaluating valve manufacturers in Saudi Arabia, engineers often look beyond price. Questions such as material traceability, pressure ratings, testing procedures, and after-sales support matter far more in the long run.

Kinds of Valves in Piping: Practical Understanding for Engineers

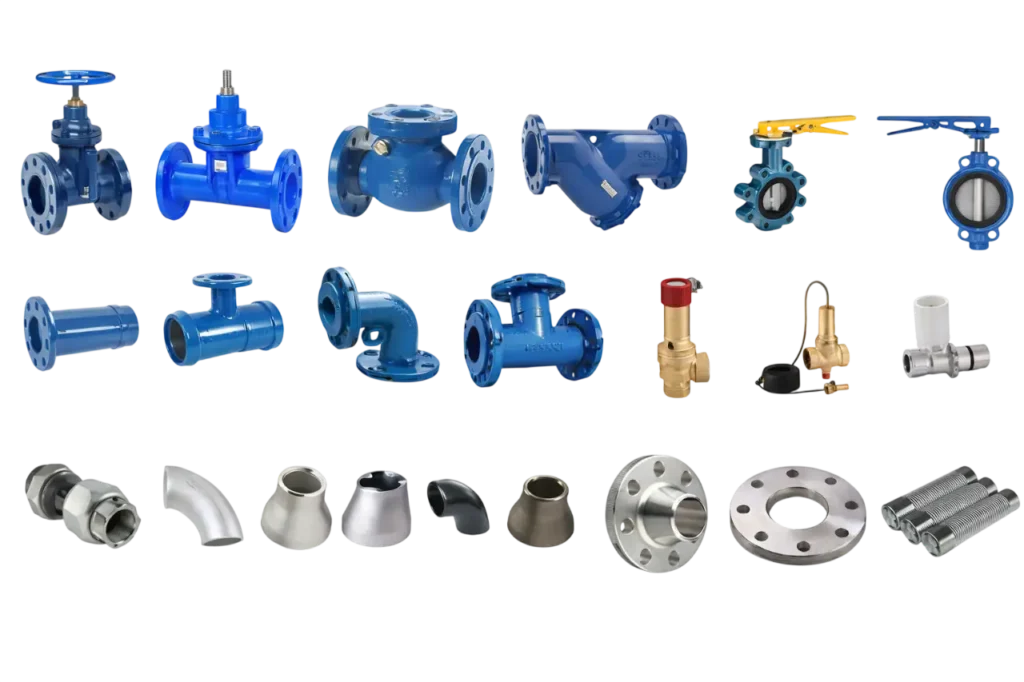

Understanding the kinds of valves in piping helps engineers to select the right valve from the right service, so that you can get the product according to your needs.

Gate valves are commonly used for isolation in pipelines where full open or full close operation must be required. You have to choose globe valves when precise flow control is needed, especially in utility and process lines. Ball valves are common across the Saudi oil & gas facilities only because of their tight shut-off and fast operation. Butterfly valves are often used for large-diameter water and HVAC systems, where weight and space are considerations. Check valves plays a important role in protecting pumps and compressors by preventing the backflow.

In instrumentation systems, specialized valves such as manifold and angle valves are essential. For example, angle valves in Saudi Arabia are often used where flow direction must change under pressure, while maintaining control and safety.

The Role of Flanges in Valve Installation

Valves cannot function effectively without proper piping connections. Flanges provide these connections, and incorrect flange selection can compromise the entire system.

In Saudi Arabia’s industrial plants, flange selection is often dictated by pressure class, temperature, and maintenance requirements.

Grooved Flange in Industrial Systems

A grooved flange is commonly used in fire protection systems, HVAC networks and in utility piping too. These flanges allow fast installation without welding which is particularly useful in the large facilities where downtime must be minimized.

In Saudi infrastructure projects, grooved flange systems are valued for their flexibility and ease of maintenance, mainly in the non-critical pressure services.

Weld Neck Flange for High-Pressure Applications

For the high-pressure and all high-temperature services, the weld neck flange is the preferred option. Its tapered hub helps to reduce all the stress concentration which is making it ideal for oil & gas pipelines, refineries and for the petrochemical plants too across Saudi Arabia.

Most reputable valve manufacturers in Saudi Arabia ensure their valves are compatible with ASME-rated weld neck flanges for critical services.

Raised Face Flange as an Industry Standard

The raised face flange is the most commonly used flange type in industrial piping. It allows effective gasket sealing and is suitable for a wide range of pressures and temperatures.

You will find raised face flanges in water treatment plants, chemical facilities, power stations, and general process industries throughout Saudi Arabia.

Blind Flange for Isolation and Safety

A blind flange is used to close off pipeline ends or pressure vessel openings. It is particularly useful for maintenance, hydrotesting, and future system expansion.

Because blind flanges must withstand full system pressure, quality and material selection are critical—especially in Saudi oil & gas facilities.

Lap Joint Flange for Maintenance-Friendly Systems

A lap joint flange is used with a stub end and is ideal for systems requiring frequent dismantling. It allows easy alignment and reduces installation effort.

Although not suitable for very high-pressure services, lap joint flanges are practical in corrosive and maintenance-heavy environments commonly found in process industries.

Integration of Valves with Automation and Instrumentation

Modern industrial plants in Saudi Arabia are increasingly automated. At this time valves are no longer isolated mechanical devices because from now they are only a part of integrated control systems.

If you are working with a trustable instrumentation supplier in Saudi Arabia then it ensures that valves, actuators, transmitters and the controllers work together seamlessly. Automation components such as PLC cards in Saudi Arabia play a key importance in valve control and the monitoring.

Sensors are equally important. Many plants rely on IFM sensors in Saudi Arabia to monitor flow, pressure, and temperature, ensuring valves operate within safe limits and reducing the risk of failure.

Global Valve Brands and Trusted Suppliers in Saudi Arabia

Saudi industries often prefer globally recognized brands only for their proven reliability and compliance with international standards. Leading valve manufacturers in Saudi Arabia typically supply these brands through the authorized local partners.

For instrumentation and control applications, Hylok suppliers in Saudi Arabia provide high-quality valves and fittings used in control panels and process systems. In hydraulic and pneumatic applications, Parker suppliers in Saudi Arabia support a wide range of industrial needs.

Instrumentation systems also rely heavily on manifold valves in Saudi Arabia for pressure measurement, isolation, and calibration, particularly in oil & gas and petrochemical facilities.

How You Can Choose the Right Valve Manufacturer in Saudi Arabia

Selecting the right supplier is more about than only comparing prices. Experienced engineers and procurement teams in Saudi Arabia always focus on dependability, compliance and on the long-term support too.

You can start it by verifying that the supplier meets international standards or not like API, ASME, and ISO. You should check whether they can provide material test certificates, pressure ratings and technical datasheets. Local stock availability is another key factor as it directly affects the project timelines. Finally, assess whether the supplier understands Saudi operating conditions and also the industry requirements.

If you need technical guidance or product recommendations, it is always wise to contact our experienced valve suppliers in Saudi Arabia who could support you from specification to commissioning.

Conclusion: Making Informed Valve Decisions in Saudi Arabia

As Saudi Arabia continues to expand its industrial and infrastructure projects, the demand for trustable flow control solutions are increasing day by day. Choosing the right valve manufacturers in Saudi Arabia is important so that it can ensure safety, efficiency and also for long-term operational success.

By understanding the kinds of valves in piping, selecting appropriate flange types such as grooved flange, weld neck flange, raised face flange, blind flange, and lap joint flange, and working with trusted local suppliers, industrial buyers can significantly reduce risk and maintenance costs.

For engineers and procurement professionals, informed valve selection is not just good engineering practice—it is smart business. For a general technical overview of valves as mechanical devices, you can also check this article on Valve – Wikipedia.

Making the right choices today will ensure safer, more reliable operations tomorrow.